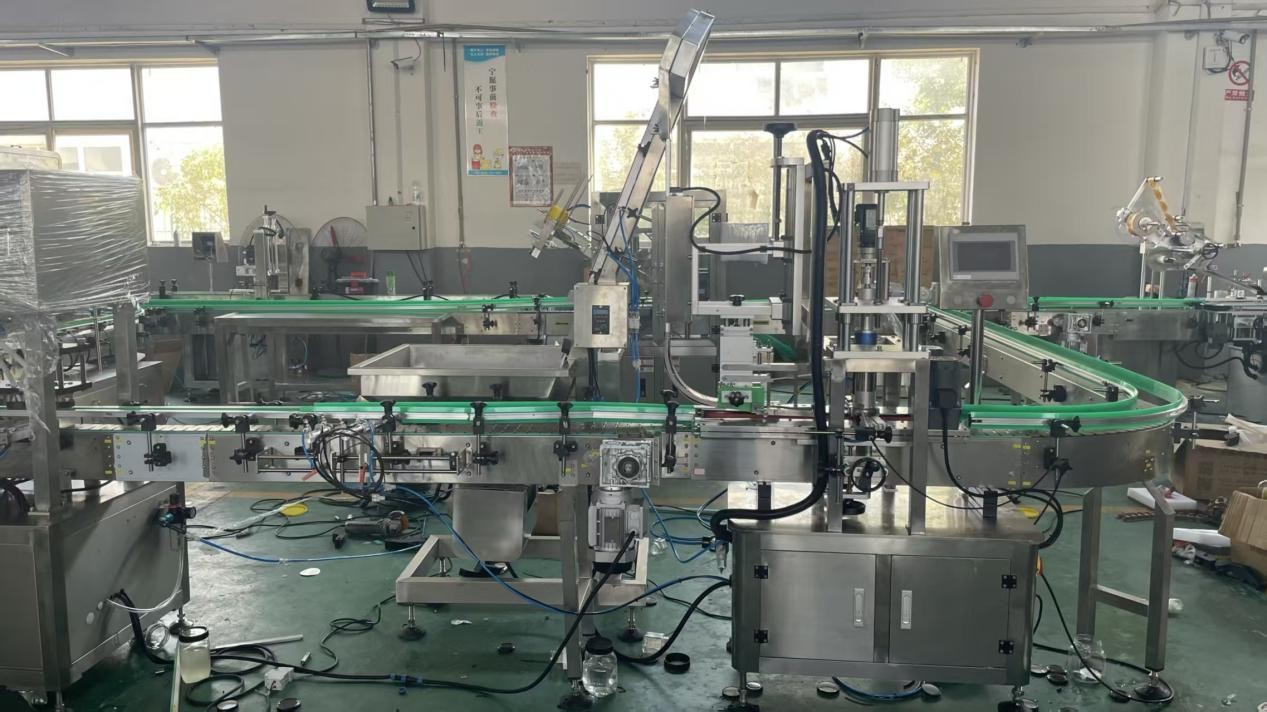

Servo Capping Machine

The servo capping machine is the core equipment for achieving precise cap sealing of honey bottles in the fully automatic honey filling production line. It adopts servo motor drive and torque closed-loop control technology, enabling automatic cap feeding, thread engaging, and tightening for honey bottles. The control accuracy of capping torque is ±0.05N・m, and the sealing qualification rate is ≥99.8%, which effectively prevents honey from leaking and getting damp during transportation. It can be seamlessly connected with the bottle mouth film-sealing leveling and cutting machine and the labeling machine, complying with the food production hygiene specifications of GB 14881-2013. Various types of bottle caps can be tightened by replacing the mold.

Equipment Description (Refer to the single-machine manual for specific usage methods)

- Cap Feeding Unit: It consists of a magnetic suction type lifting cap sorter (which lifts caps with strong magnetism), cap guide rails (to prevent cap jamming), a thread engaging structure, and a cap feeding manipulator. It can automatically arrange messy caps in a uniform direction and convey them to the capping station.

- Capping Unit: The core part is a servo motor-driven capping head (equipped with replaceable jaws to adapt to different bottle caps).

- Positioning and Conveying Unit: It uses a conveyor belt whose speed matches that of the preceding equipment, and is equipped with photoelectric sensors (to detect the in-place signals of bottles and caps). Guardrails are installed on both sides of the conveyor belt to prevent bottles from toppling over.

- Control and Monitoring Unit: It is equipped with a touch screen + PLC control system, which can set parameters such as capping torque, rotation speed, and conveyor belt speed.