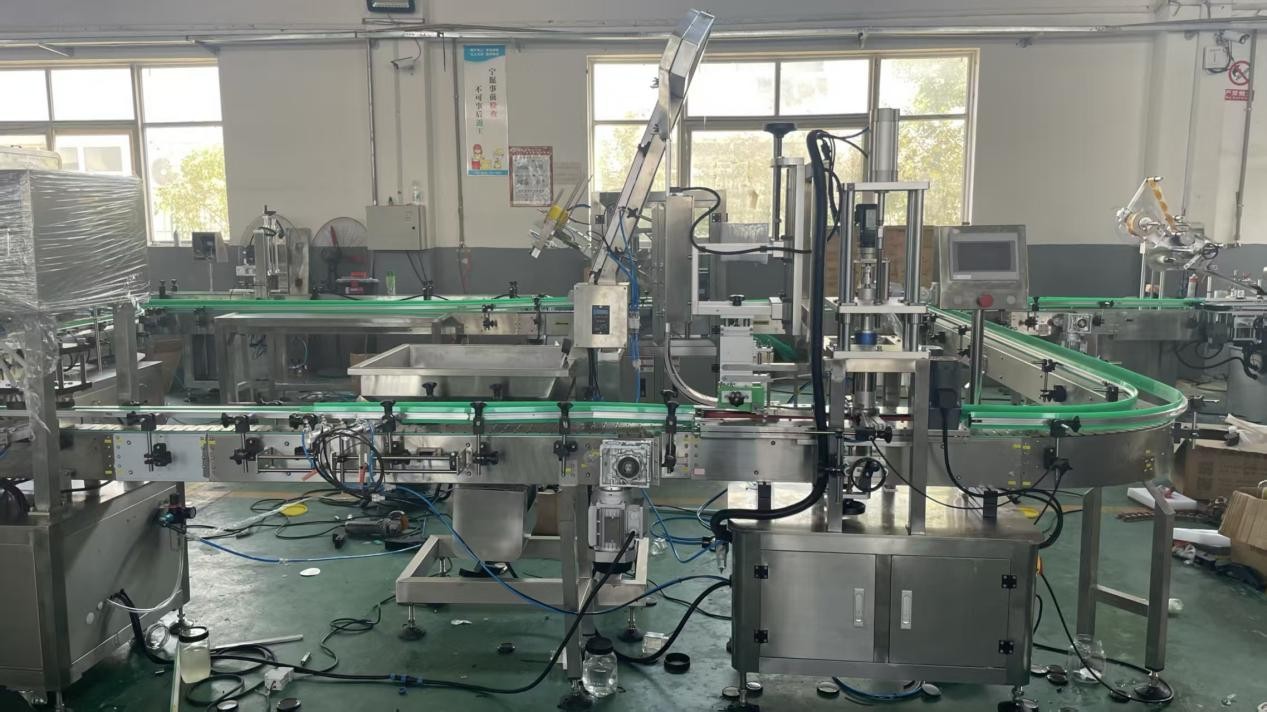

I. Overview of the Production Line The fully automatic honey filling production line is an automated production equipment specially designed for high-viscosity fluids such as honey. It integrates full-process functions including bottle washing, sterilization, filling, weight detection and rejection, bottle mouth film sealing, cap arranging, cap screwing, labeling, coding, and finished product packaging and conveying, enabling automated operations from empty bottles to finished honey products. The parts of the equipment that come into contact with materials are made of 316 stainless steel, and the metal parts of the machine body are made of 304 stainless steel, which complies with food hygiene standards. It has the characteristics of high filling accuracy (error ≤ ±1%), high production efficiency (with a capacity of 1,200-1,500 bottles per hour based on 500g products), and easy operation. It is suitable for filling honey bottles of different materials (such as glass and PET) and different specifications (100g-1,000g).

II. Process Flow of the Production Line This fully automatic honey filling production line is professionally designed and manufactured for honey filling production. It can realize all functions including pneumatic bottle blowing → ultraviolet sterilization → honey filling → metal detection, weight detection and rejection → bottle mouth film sealing → shaping after bottle mouth film sealing → cap hanging and screwing → automatic cap buckling → manual cap pressing → labeling → coding → film shrinking → film packaging.

Instructions for Automatic Operation of the Entire Line

Automatic Operation

1. Startup Sequence: Turn on the conveyor belt → bottle washing machine → ultraviolet sterilizer → filling machine → film sealing machine → shaping machine → cap screwing machine → labeling machine → film packaging machine → film packaging and labeling equipment in sequence. Let each equipment run under no-load condition for 3 minutes and check for abnormal noise or jamming.

2. Material Introduction: Open the discharge valve of the buffer storage tank to allow honey to enter the material tank of the filling machine. When the liquid level in the material tank reaches the set maximum level, the filling machine starts to work.

3. Full-Process Operation:

The bottle washing machine automatically rinses the interior of empty bottles, which are then conveyed to the ultraviolet sterilizer. After sterilization, the bottles are transported to the filling station.

The filled honey bottles are conveyed via the conveyor belt to the bottle mouth film sealing machine, shaping machine and cap screwing machine, where caps are automatically picked and screwed on.

The bottles with screwed caps enter the labeling machine to complete labeling, and finally are transported to the film sealing and labeling area via the conveyor line.

III. Equipment Composition List of Fully Automatic Filling Production Line

|

SN |

Name |

Model |

Quantity |

Remarks |

|

1 |

linear machine for rinsing cans with air |

HC-GZ-280 |

One (unit) |

|

|

2 |

UV sterilization machine |

HC-XD-180 |

One (unit) |

|

|

3 |

2-head filling machine with tracking |

HC-GZJ-180 |

One (unit) |

|

|

4 |

integrated metal detector and control scales |

HC-JZYTJ-180 |

One (unit) |

|

|

5 |

machine for feeding and installing PET cans |

HC-XGJ-180 |

One (unit) |

|

|

6 |

automatic capping machine for screw caps |

HC-YGJ-120 |

One (unit) |

|

|

7 |

automatic (6 heads + 3 heads) aluminum membrane sealing machine for cans |

HC-FMJ-180

|

One (unit) |

|

|

8 |

labeling machine with 3 heads |

HC-SMT |

One (unit) |

|

|

9 |

laser marker |

TYMFS-120 |

One (unit) |

|

|

10 |

shrink wrap machine |

LC-MB6535 |

One (unit) |

|

|

11 |

automatic marking machine |

HC-TBJ-120 |

One (unit) |

|

|

12 |

integrated transportation system (including drive motors) |

HC-SSJ-280 |

One (unit) |

|

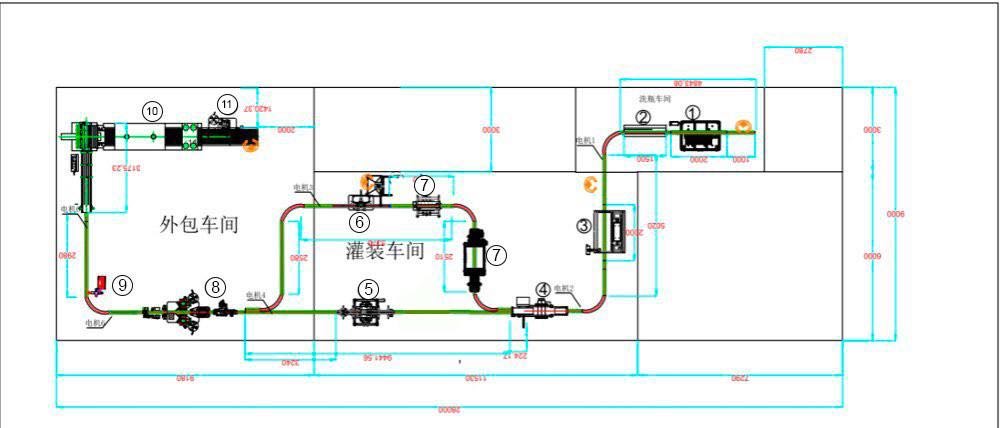

IV. Layout Diagram of the Entire Line Equipment

V. Applicable Bottle Types (Samples Provided)